CASQ-it for Your Business Processes

For quality planning, quality assurance and quality management

Modular. Integrative. CASQ-it.

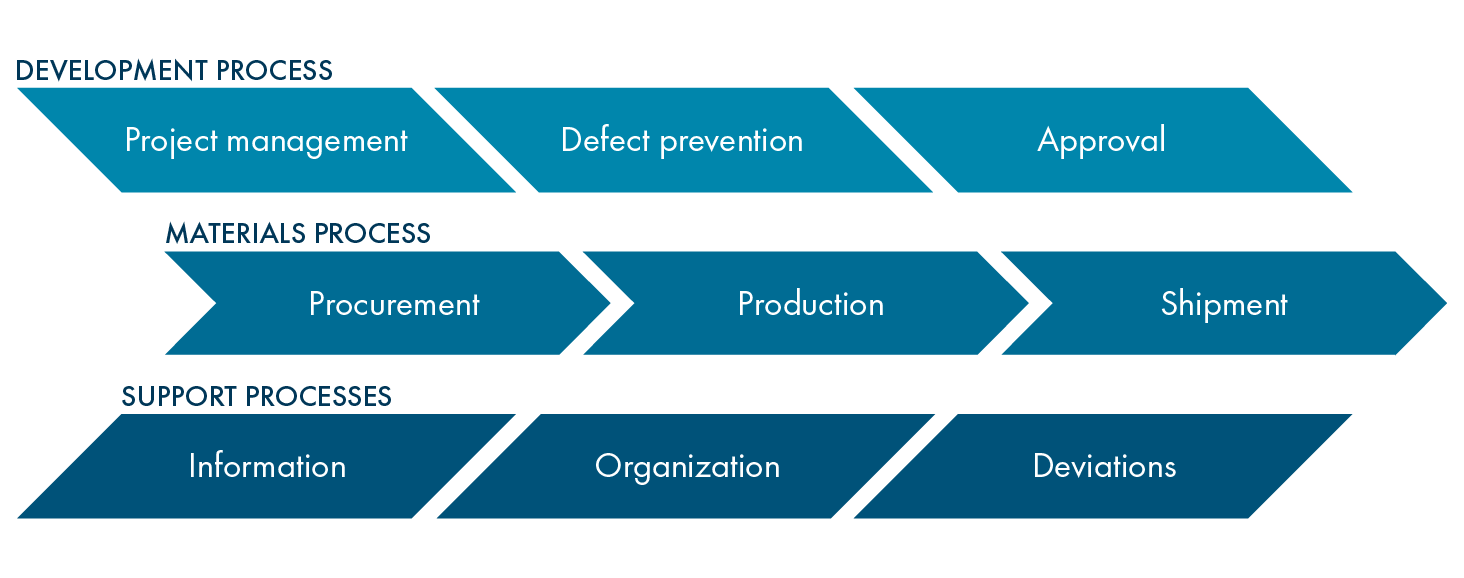

Flawless business processes lead to flawless products. That's why CASQ-it covers all process steps from quality planning and quality assurance to quality management, spanning development processes, material processes and supporting processes. The advantage of CASQ-it lies in this process-oriented method, which allows the CAQ software to adapt flexibly to your processes ‒ not the other way around.

CASQ-it supports your quality management journey into the future. With higher quality and reliability, you boost customer satisfaction while reducing your quality costs. Discover the benefits of CASQ-it — one of the most successful CAQ solutions for quality management, trusted and proven by over 30,000 users.

Want to gain a general overview of CAQ and understand what it can do for your business? We've put together the key information you need about CAQ.

Highlights of the CAQ Software

CASQ-it at a glance: Processes and Modules

Get Your Free Info Package

Development Process

CASQ-it stands for systematic error prevention already in the development process and holistic quality planning. Already in the first phase of product development, the CASQ-it modules support your project management, risk assessment, process planning and gauge management right up to the product part approval process.

APQP:

Software for Successful Project Management

Full transparency across statuses, milestones and resources

FMEA:

Software for Risk Analysis and Failure Prevention

Evaluate potential risks in product and process failures

CPL:

Control Plan Software for Process Planning

Maximum efficiency across prototype, pre-production and series production processes

PPL:

Intelligent Inspection Planning Software

All inspection processes in one inspection plan structure

GMS:

Gauge Management Software for Reliable Operations

Ensure reliable gauges through capability analyses and monitoring

PPAP:

Software for Product and Process Approval

Process control with resampling and requalification inspections

Material Process

CASQ-it systematically monitors your material process so that errors can be detected and corrected at an early stage. In this process, the CAQ system respects the specifics of your production lines (single, small-batch, batch and mass production). CASQ-it helps you reliably control the quality and efficiency of your processes in procurement, production and shipping.

IGI:

Incoming goods inspection and supplier management

Automated inspection order generation and consistent supplier evaluation

MESQ-it:

Manufacturing Execution System

Efficient production management with an integrated workspace

BII:

Batch and Intermediate Inspection

Reduced inspection effort through intelligent dynamic inspection rules

SPC:

Statistical Process Control

Optimized process quality for series and mass production

OGI:

Outgoing Goods Inspection

Reduced inspection and documentation costs, fewer customer complaints

Supporting Processes

CASQ-it ensures efficiency and quality in your supporting processes: The CAQ system reliably supports you in the claims and root cause analysis with integrated workflows for claims processing. CASQ-it centralizes all measures, and controls on-time processing. Audits monitor the quality of your processes in the overall organization. And for all processes, CASQ-it provides reliable quality information in the form of KPIs and analyses to support your business decisions.

TMS:

Task Management System

Company-wide control, tracking and monitoring of tasks

QWM:

Quality Workflow Manager

Automated management of complaints and business processes

CMEA:

Complaints Management and Error Analysis

Continuous improvement processes leading to complete resolution

WM:

Warranty Management

Fast and concentrated analysis of the current field situation

AUDIT:

Audit Management

Planning, scheduling, analysis and integrated task management

Your Point of Contact

Would you like to find out more about our digital solution for quality management?

With his many years of experience, Guido Goldammer is your ideal point of contact for all questions about this topic.

/bw_400x200-Lederer.png?width=400&height=200&name=bw_400x200-Lederer.png)