Intelligent Inspection Planning Software

All inspection processes in one inspection plan structure

Fast and Easy Inspection Planning

Reduce administrative effort by up to 90%

Our inspection planning software, CASQ-it IPL, integrates all inspection processes into a unified inspection plan structure. As an integral part of CASQ-it modules for Incoming Goods Inspection, Outgoing Goods Inspection, Batch Inspection, Statistical Process Control (SPC), and Gauge Management , CASQ-it IPL systematically streamlines your inspection planning. Thanks to intelligent features such as master and family inspection plans and DIN-compliant buttons, inspection planning becomes not only intuitive and easy but also exceptionally fast.

Under ideal conditions, these features can reduce your administrative workload in inspection planning by up to 90%.

CASQ-it IPL can operate as a standalone solution or seamlessly integrate with other CASQ-it modules — providing a tailored solution to meet your specific requirements.

Benefits of Our Inspection Planning Software

How CASQ-it IPL supports your inspection planning

Inspection Planning Software in the Development Process

Data Transfers

With CASQ-it IPL, you can create your inspection plans easily by importing dimensions from CAD drawings, transferring part master data from your ERP/PPS system, and deriving inspection plans from the Control Plan.

Previously used inspection plans or master inspection plans accelerate your inspection planning through inheritance. DIN-compliant buttons support you with catalogs for fast tolerance determination.

Structure Planning

Structure Planning

Inspection sequences, family inspection plans, and single- and multi-level defect catalogs ensure precise mapping of your product and process structures.

Dynamic inspection severity adjustments reduce inspection effort so that you inspect only as much as necessary. Validity limits for inspection plans and integrated supplier approval checks are provided for added security.

Optimize your inspection processes

Detailed Planning

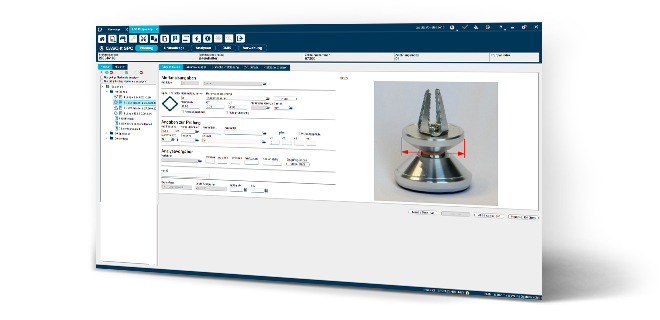

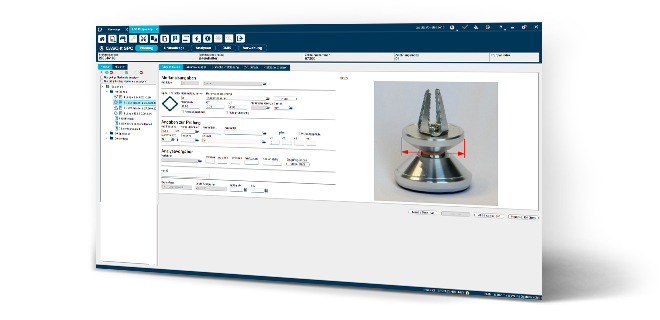

CASQ-it IPL addresses your employees' needs with a clear inspection structure and supporting information: Through graphical inspection planning, you can visually highlight characteristics details and provide your employees with additional guidance by adding inspection instructions, photos and drawings.

Inspection Plan History

CASQ-it IPL automatically documents all changes for you: The inspection plan history and the product lifecycle record every change, in compliance with DIN EN ISO 9001, ISO/TS 16949 and VDA standards.

Centrally configured characteristic types control the inspection behavior throughout the system — whether for functional, visual, dimensional or assembly inspections — with sampling plans or 100% inspection, exactly as your processes require.

What Is an Inspection Plan?

Inspection plans are a key component of quality planning in the development process. Given the scope and associated effort, it is essential to carefully plan the inspection of manufactured parts, products, or services. Only with proper planning can you ensure that defect-free parts move on to the next process step.

Inspection plans define how the quality inspection of your products should be conducted to ensure compliance with quality requirements.

In the inspection plan, you specify not only which characteristics are to be inspected but also the sequence in which inspection operations are to be carried out. With our comprehensive software, you can easily create inspection plans for incoming goods inspection, SPC, in-process inspections for single-item, small batch, series and mass production, as well as inspection plans for outgoing goods inspections directly from the control plan.

This significantly reduces the administrative effort required for inspection planning.

Your Point of Contact

Would you like to find out more about our digital solution for quality management?

With his many years of experience, Guido Goldammer is your ideal point of contact for all questions about this topic.

FAQ About Our Inspection Planning Software

CASQ-it IPL is an intelligent inspection planning software that integrates all inspection processes into a unified, centrally managed plan structure. It reduces costs by avoiding duplicate data entries and speeds up inspection planning through plan inheritance and dynamic inspection severity adjustment. This allows you to cut administrative effort in inspection planning by up to 90%.

The software simplifies inspection plan creation with an intuitive interface and automatic data import from CAD drawings or ERP/PPS systems. Existing inspection plans can be reused and adapted through plan inheritance and the use of template plans, significantly accelerating system implementation.

CASQ-it IPL supports both qualitative and quantitative inspection characteristics, collective and document-linked characteristics, as well as inspections with batch and serial number tracking. The inspection methods are highly flexible and can be adapted for in-process inspections during single-item, small batch, series and mass production.

With features such as tabular quick entry, CAD data import, dynamic inspection severity adjustment and centralized configuration of characteristic types, CASQ-it IPL minimizes inspection efforts. Error catalogs and supplier approval checks ensure security and consistency throughout the inspection process.

Yes, CASQ-it IPL is fully integrable with other CASQ-it modules such as Statistical Process Control (SPC), Production Part Approval Process (PPAP), Audit Management (AUDIT) and Gauge Management (GMS). The software also allows for data import from ERP/PPS systems and CAD drawings, ensuring seamless integration into your existing workflows.

/bw_400x200-Lederer.png?width=400&height=200&name=bw_400x200-Lederer.png)