Software for Process Data Collection and Processing

Process data collection with MESQ-it is one of the key components in achieving full analysis and control of your production processes.

MESQ-it captures process data from production in real time, ensuring that warning limits are monitored, maintenance jobs are triggered on time and quality assurance data is reliably delivered.

The software for process data collection (PDC) is an integral part of MESQ-it, which encompasses a range of functional areas.

Benefits of Our Process Data Collection Software

Collect Process Data in Real Time

Efficient Process Data Collection – Key Features at a Glance

Plug and Play

With MESQ-it process data collection, you can define at the push of a button which machine data should be collected for process analysis. You also have the flexibility to assign custom labels to individual measurement variables. All settings can be easily adjusted at any time to meet changing requirements.

Automatic Data Collection with Alarm Management

Automatic Data Collection with Alarm Management

The MES receives process data from your machines in real time. With a simple click, you decide whether process data should be collected continuously or only during active production cycles. Automatic data collection saves time and reduces potential error sources.

Data can be retrieved:

- Automatically

- Continuously or at defined intervals

- Individually, for example, based on quantity produced, specific value changes or particular process steps

Process Data Analysis

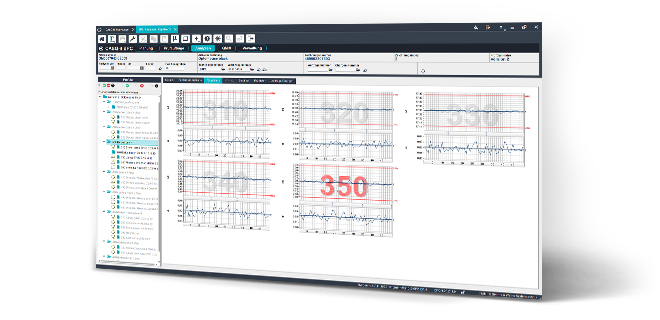

With production monitoring, you always have all relevant data at your fingertips. Changes in production are displayed through online data analysis. You can freely select which process data you want to view, from which machine and for which time period, enabling precise and transparent comparisons of machine data.

Understanding the Impact of Process

Understanding the Impact of Process

and Product Characteristics on Quality

In combination with CASQ-it SPC, you can easily compare product, quality and process characteristics in a control chart. This helps you detect interdependencies between production parameters and product quality, enabling you to optimize your production processes.

Irrelevant data can easily be filtered out.

Connecting process data collection with CASQ-it SPC allows you to:

- Analyze process and quality data together

- Automatically start and stop measurement jobs based on process data, such as reaching a defined quantity

- Identify correlations between process data and product quality

- Improve the quality of your production processes

With MESQ-it Process Data Collection, you have full control over your production data. Use this data to optimize production workflows, increase resource efficiency and enhance product quality – all in real time.

Learn More About Our Solution

Your Point of Contact

Would you like to find out more about our digital solution for production management?

With his many years of experience, Alexander Harder is your ideal point of contact for all questions about this topic.