Maintenance Management Software for Long-Term Machine Availability

Our maintenance management software supports your total productive maintenance strategy by ensuring the long-term availability of your machinery, equipment and tools.

It features a concise master data sheet for each operating resource. The dynamic interval monitoring feature informs you well in advance of all your upcoming servicing jobs – based on the respective service intervals or machine operating cycles. The time scheduled for these jobs is automatically taken into account during job processing.

The software guides you through maintenance, servicing and inspections based on your work schedules. Close integration with your ERP system ensures that spare parts needed for repairs are ordered immediately. The history contains detailed logs that provide verifiable documentation of all completed servicing and maintenance activities. Comprehensive analytics offer clear insights into costs, maintenance intensity and spare parts requirements.

Benefits of Our Maintenance Management Software

Maximize equipment availability, minimize downtime

How the Maintenance Management Software Works

Our maintenance management software can be deployed flexibly to meet your preventive maintenance needs:

- As a standalone solution that comprises everything you need to manage your preventive maintenance activities

- As an integral part of MESQ-it, in compliance with VDI Guideline 5600

- In seamless interaction with CASQ-it

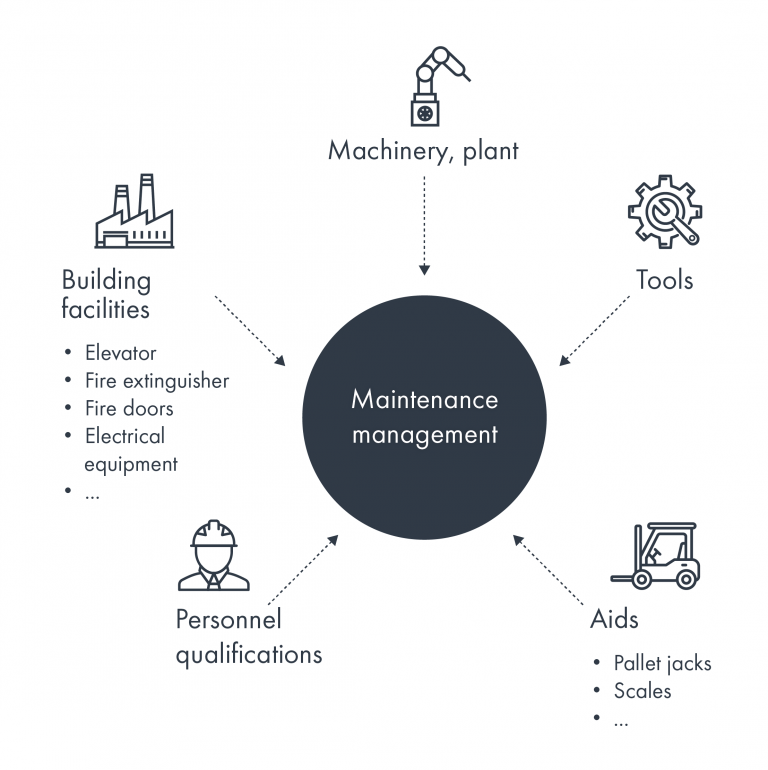

What Maintenance Management Means

Maintenance management encompasses all activities aimed at preventing machine failures and increasing equipment availability. Maintenance measures not only optimize operational workflows but also improve operational safety. Generally, there are three maintenance strategies:

- With corrective maintenance, action is only taken after an unforeseen failure or breakdown occurs.

- Preventive maintenance aims to avoid such failures and breakdowns through planned, regularly scheduled maintenance, servicing and inspection activities.

- Predictive maintenance relies on forecasting the wear progression of machines, equipment and tools. Its goal is to determine the economically optimal maintenance interval.

Maintenance KPIs consolidate information about maintenance processes and serve as a foundation for improving efficiency in what is often a cost-intensive area of operations.

Maintenance Management Software from Böhme & Weihs

Resource Management

All information about your operating resources is contained in concise master data sheets. They include defined maintenance intervals and associated maintenance schedules.

For tools, additional data is available, including supplier details, purchase prices and dates, stock levels and drawing numbers, possible storage locations, bills of materials, and information about cavities. Individual cavities can be easily deactivated with a single click if necessary.

Each master data sheet also contains the relevant work schedules for the maintenance, servicing and inspection activities associated with the resource in question. Maintenance intervals are defined dynamically, either based on the respective service interval or machine operating cycle.

Our preventive maintenance solution is a comprehensive management tool – not just for production equipment, but also for monitoring auxiliary equipment such as fire extinguishers or elevator systems.

To ensure operational safety and functionality, the maintenance management software tracks maintenance intervals and sends early reminders when inspections are due.

It also monitors employee qualifications tied to renewal cycles, such as welding certifications, ensuring that qualifications remain up to date.

Generation of Maintenance Schedules

Generation of Maintenance Schedules

The maintenance management software coordinates all activities required to ensure the functionality of your resources through proactive maintenance, inspection and servicing.

The necessary work schedules, including the respective time schedules, can be conveniently defined for this. A structured breakdown of work steps ensures that every task is clearly mapped – from simple cleaning instructions for machine operators to complex maintenance procedures for service technicians.

To make instructions even clearer, images and documents – such as sample photos and procedural guidelines — can be integrated, providing your team with helpful visual support for preventive maintenance.

Checklists displayed directly at the terminal remind employees of scheduled tasks and record the completion of each step, ensuring thorough documentation of all maintenance activities.

Deadline Monitoring

Deadline Monitoring

A special notification service helps you plan maintenance activities well in advance. You'll receive email reminders when, for example, 80% of a service interval or machine cycle has been reached. The lead time for these reminders can be freely configured in the maintenance management software.

This ensures you always have enough time to coordinate upcoming maintenance jobs – especially when external personnel need to be involved.

Get Your Free Info Package

Detailed Planning of Maintenance Jobs

Detailed Planning of Maintenance Jobs

The well-structured scheduling interface gives you an instant overview of which maintenance jobs are due and how much time has been allocated for each one.

For better orientation, the graphical maintenance dashboard can be filtered to show only specific capacity groups, such as machines or tools.

Scheduling is based on two key elements: ad-hoc notifications from production that trigger manually created maintenance jobs – for example, due to unscheduled machine downtime – and recurring maintenance activities that are automatically scheduled based on service intervals or machine cycles, always aligned with your current and planned production jobs. Assignment of qualified personnel is handled easily via drag & drop, ensuring that the right qualifications are matched to each maintenance job.

Execution

Execution

Your employees are guided step-by-step through predefined work schedules for maintenance, inspection, servicing and repair. The maintenance management software automatically documents which jobs have been completed, how long each job took, and the resulting downtime for the machinery. It also records the outcome of each job.

If repairs are needed and the resource is taken out of production, the maintenance management software triggers an intelligent event chain: Scheduled production jobs are automatically rescheduled, responsible personnel are notified by email, and the ERP system receives an automatic request for the necessary spare parts. Without delay, the system can either check inventory and reserve parts or initiate an immediate order, ensuring fast and efficient recovery.

Maintenance Analysis

Maintenance Analysis

Our maintenance management software maintains a detailed history, allowing full visibility into all completed jobs, including logs and outcomes. Powerful analysis tools provide precise insights into completed maintenance activities and highlight optimization opportunities within the maintenance process. This includes:

- OEE

- MTBF (Mean Time Between Failure)

- MTTR (Mean Time to Repair)

- Cost expenditure

- Downtime caused by maintenance activities

- Personnel deployment

Highly Flexible Deployment Options

Highly Flexible Deployment Options

The maintenance management software can be deployed flexibly to meet your company's specific requirements:

- As a standalone module for your preventive maintenance needs

- As an integral part of MESQ-it

- In seamless interaction with CASQ-it for comprehensive total productive maintenance

Your Point of Contact

Would you like to find out more about our digital solution for production management?

With his many years of experience, Alexander Harder is your ideal point of contact for all questions about this topic.