MES Software for Your Production Management

A comprehensive workspace for your processes

Comprehensive. Transparent. MESQ-it.

Our MES software, MESQ-it, targets the areas of your production processes with the greatest optimization potential by:- Increasing machine utilization

- Reducing downtime

- Optimizing lead and setup times

- Lowering inventory levels

- Improving on-time delivery performance

MESQ-it enhances your production workflows, delivers transparent KPIs and gives you real-time visibility into your machinery.

With its intuitive interface, the software helps you make your production management even more efficient.

Want to gain a general overview of MES and understand what it can do for your business? We've put together the key information you need about Manufacturing Execution Systems (MES).

The MES with a Difference

MESQ-it stands for simplicity – it’s exceptionally intuitive to use. This ensures short training times and quick access to the information you need in day-to-day production operations.

MESQ-it also stands for transparency. Thanks to its browser-based access, the software runs on any of your devices without the need for additional installation – keeping you informed at all times, whether you're in the office, on the go or at home.

Highlights of the MES Software

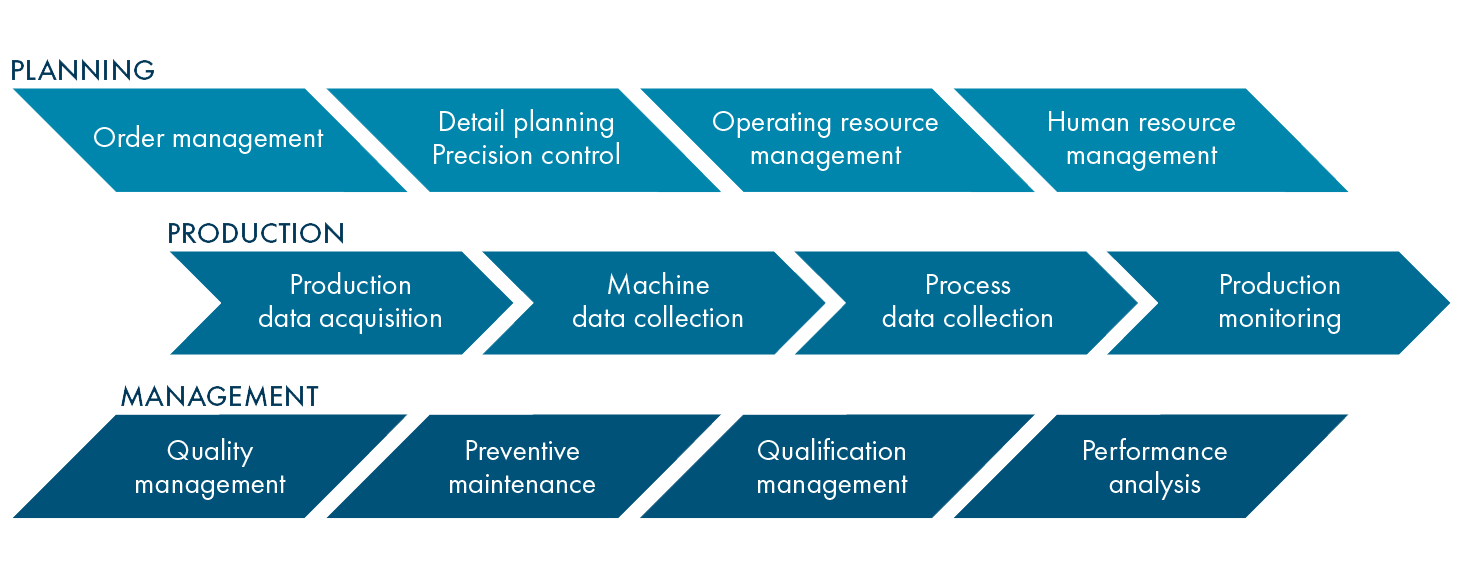

MESQ-it at a Glance: Areas and Functions

Get Your Free Info Package

Planning

MESQ-it supports you intelligently right from the planning phase. The intuitive detailed planning module serves as your control center for all planning activities – including orders, personnel, machines and tools. It helps you maintain complete visibility while factoring in all interdependencies between your resources. The digital planning board provides a full overview of all production orders, personnel assignments, tool usage and maintenance jobs.

Order Management

Smooth production through flexible order control

Detailed Planning and Precision Control

High-precision overview for intelligent production management

Operating Resources Management

Reliable assurance of resource availability and functionality

Human Resources Management

Efficient workforce planning for transparent capacity management

Production / Production Management

With MESQ-it, you maintain full control over your production – in particular when utilization levels are high or when unexpected events occur. Whether data is collected through machine connectivity or manual feedback from employees, the Production Cockpit centralizes all information and statuses from all your production areas – a real-time process visualization with zero delay.

MESQ-it also supports your workers and machine operators with an optimized interface. At both group and machine terminals, the software is designed for maximum simplicity and clarity, ensuring the best possible support on the shop floor and improving all workflows.

PDA:

Production Data Acquisition

Centralized information hub for production control

MDC:

Machine Data Collection

Intelligent real-time monitoring of all machine statuses and operational data

PDC:

Process Data Collection

Continuous gathering and analysis of process parameters

Production Monitoring

Smart control of production processes through real-time monitoring

Management

MESQ-it helps you continuously identify and fully leverage improvement opportunities.

The qualification management software lays the foundation for proactive workforce development.

With intelligent maintenance management software, you shift from reactive maintenance to preventive maintenance with a proactive, holistic approach.

The KPIs and analyses provided by MESQ-it enable targeted root cause analysis to uncover weaknesses in the production process and identify untapped resources. MESQ-it thus becomes an objective foundation for sustainable cost-saving strategies, consistent quality and intelligent resource utilization.

Quality Management

For quality planning, quality assurance and comprehensive quality management

Maintenance Management

For ensuring the long-term availability of your machines, equipment and tools

Performance Analyses

Interactive performance analyses and MES KPIs

Your Point of Contact

Would you like to find out more about our digital solution for production management?

With his many years of experience, Alexander Harder is your ideal point of contact for all questions about this topic.