MACHINE DATA COLLECTION – THE BASICS

Published: March 10, 2021

Last update: August 20, 2025

Machine data collection – all the most important information put together for you in a clearly structured and comprehensive summary:

- What does machine data collection (MDC) mean?

- Machine data collection and production data acquisition

- What are the tasks of machine data collection?

- What does machine data collection aim to achieve?

- What are machine data?

- What advantages does machine data collection offer?

- How automated machine data collection is carried out?

- Reliable machine data collection using the right software

WHAT DOES MACHINE DATA COLLECTION (MDC) MEAN? – DEFINITION

Machine data collection, abbreviated to MDC, refers to the process of recording and storing information associated with the production and manufacturing processes and making this accordingly available. MDC thus describes the interface between the machines in the production process and your information processing system. Collecting machine data digitally is the first step towards digitizing the whole production process. This is because machine data collection brings transparency to your production processes through automatically collecting and storing information and making this accordingly available. An MDC solution, where information is automatically recorded, consolidated and visualized in real time, is the basis for an efficient production management system as envisaged in the Smart Factory concept.

MACHINE DATA COLLECTION AND PRODUCTION DATA ACQUISITION

MDC is part of your production data acquisition system, abbreviated to PDA. Production data acquisition is an umbrella term for the collection of actual data on the conditions and processes at a company. Machine data collection, which is the source of the data for your production data acquisition system, is used for a multitude of purposes, such as controlling processes using automatic or statistical methods (SPC) or for planning and controlling production orders.

WHAT ARE THE TASKS OF MACHINE DATA COLLECTION?

The tasks of machine data collection at a glance:

- Recording production quantities

- Real-time machine monitoring

- Reporting machine malfunctions

- Analyzing production processes

- Analyzing the reasons for malfunctions during downtime

WHAT DOES MACHINE DATA COLLECTION AIM TO ACHIEVE?

Machine data collection provides machine and production-related actual data, thus enabling your manufacturing processes to be analyzed and optimized with the aim of increasing the productivity of your manufacturing processes. In addition, the order planning process can also be optimized through the evaluation of transparent information on machine utilization.

WHAT ARE MACHINE DATA?

Machine data comprise all information accumulated in connection with a machine, whereby a distinction is made between two types of data: Product and process data.

- Process data comprise information that is required to operate a particular machine, as well as information that is directly generated through the operation of this machine. These data primarily incorporate control and consumption data and also help to monitor the processes.

- Product data comprise information that is created during the production process. These are measured at special processing units and provide information on how the production is running and on the quality of

Specifically , these machine data include:

- Production volumesYields, reject quantities

- Utilization

- Run times

- Availability and reliability

- Machine status

- Disruptions and downtime

- Energy consumption

WHAT ADVANTAGES DOES AUTOMATIC MACHINE DATA COLLECTION OFFER?

Through an automated machine data collection system, optimization potential in the production area is systematically revealed and performance increased. The status of the machine is displayed in real time.

This gives rise to numerous advantages:

- Optimization of machine run times

- Increase in machine availability

- Reduction in set-up and lead times

- Machine utilization overview

- Service intervals can be planned better

- Recording of quality data

HOW AUTOMATED MACHINE DATA COLLECTION IS CARRIED OUT

Modern manufacturing equipment generally fulfills the requirements for providing and directly transferring machine data. For existing facilities that do not have a programmable control system, a corresponding interface can be retrofitted. As soon as the machine data have been recorded, they are available to your Enterprise Resource Planning system (ERP), your Advanced Planning and Scheduling system (APS) and your Manufacturing Execution System (MES).

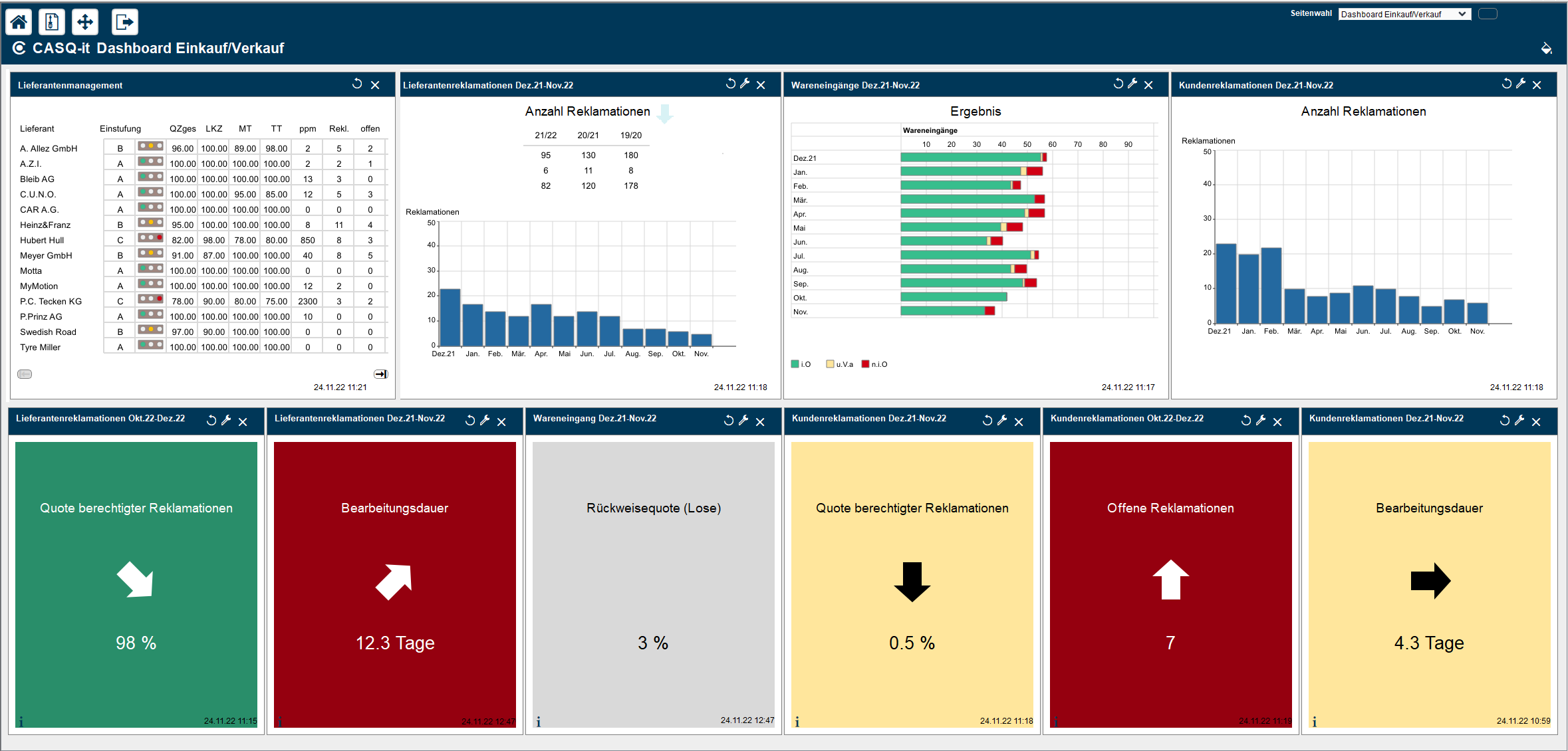

RELIABLE MACHINE DATA COLLECTION USING THE RIGHT SOFTWARE

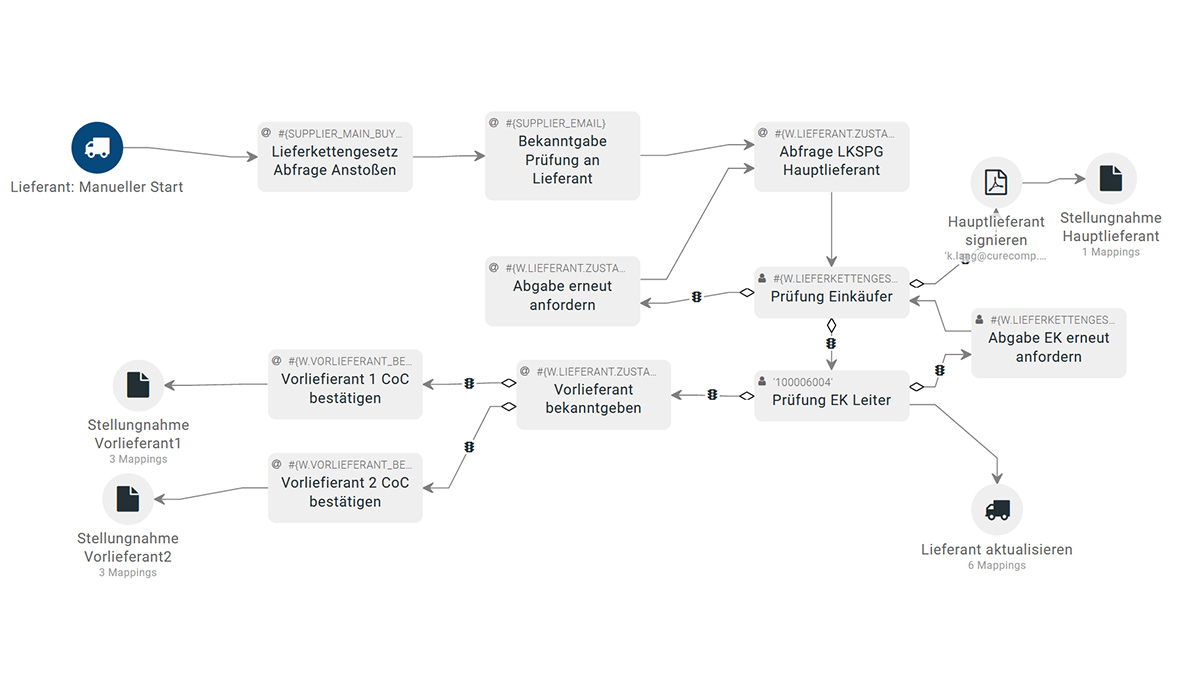

Automated machine data collection is part of a Manufacturing Execution System (MES). In order to systematically collect machine data, you need software that can be integrated into your production process and which communicates with your machines and systems. Our solution for machine data collection is an integral part of our MESQ-it MES software package. Your machines are networked to your MES through connections via WEB I/O modules, direct communications with your machine and system controller (PLC) and the exchange of manufacturer-specific data communication protocols. MESQ-it uses the established OPC UA communication standard for data transmission.

What you should take into consideration when choosing your MES software:

- Intuitive system operation: Being able to intuitively operate your software not only facilitates its acceptance but also the training of the employees who have to work with it.

- Simple visual representation of your machine data: Data that are displayed graphically make it easier to evaluate the new indicators gained from the automated data collection process.

- Flexibility of the machine data collection process: Make sure that you can adapt the rules for transferring machine data yourself without having to intervene in the machine control system. This allows you to react to dynamic processes.

Do you have any questions on machine data collection or how to reliably collect machine data using an intelligent software solution, such as MESQ-it? Then please feel free to contact us.